Everything is,

For the smiles of our customers."

Our Food,

Our promise.

In recent years, several major accidents and recalls have made headlines in the food industry, raising consumer interest in food safety. Problems with foreign substances in raw materials, unsanitary conditions in the manufacturing process, and inaccurate labeling. These factors are preventing us from enjoying our food with peace of mind.

The food accidents involving bento manufacturers that are still fresh in our minds have caused us to distrust not only our own bento manufacturing industry, but the food industry as a whole. We should not have to suffer the disastrous consequences caused by the products we have purchased for our enjoyment.

As a food manufacturer, we at 荻野屋 deeply understand the background behind such accidents. And we believe that our greatest responsibility is to deliver safe, high quality food products to our customers.

Our manufacturing system has been under strict control since before the world became more concerned with sanitary management as it is today. This is because our basic premise was that food products are directly put into our mouths, and that guaranteeing the quality of our products leads to the satisfaction of our customers.

Transparency and safety are required with regard to the food products we handle, from the source of each ingredient to the manufacturing process and storage methods.

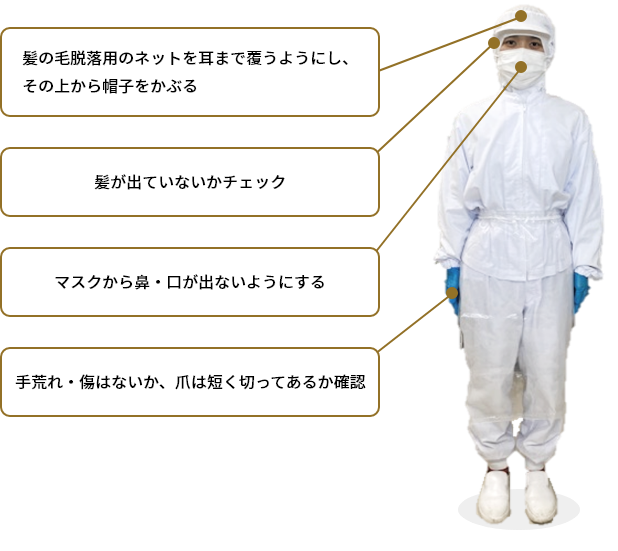

Every step of the process, from the selection of raw materials to the delivery of products to our customers, is inspected and evaluated to ensure high quality and safety. Each and every one of our employees is committed to our mission of ensuring food safety.

The current situation of food accidents may be severe. However, we at 荻野屋 will continue to make every effort so that our customers can enjoy our products with peace of mind.

Our food, that is our pride. And it is our promise to our customers.

OGINOYA has been introducing sodium hypochlorite, a disinfectant solution that is now common, and ethanol disinfection for about 50 years.

In 2010, the company received Gunma Prefecture Voluntary Hygiene Management Certification for food products, recognizing that its hygiene management based on the HACCP concept is above a certain level.

We have never forgotten that "safety and security" are the key to "deliciousness.

Sterilized with ethanol

After careful hand washing, use ethanol to disinfect even the tips of the fingers.

Careful hand washing

To ensure constant hygiene, hand washing and disinfection is always performed every 30 minutes.

jet air

Jet air is applied to the entire body to remove dust and debris from clothing.

Check heating conditions

Ensure that cooked ingredients and rice are adequately heated and temperature controlled.

Check disinfectant solution

Change the disinfectant solution approximately every two hours. Check the concentration and replace immediately if there is a smear.

germicidal lamp

Sterilizing lamps that generate ozone are installed throughout the plant. This eliminates odors.

Cleaning of recycling kettles

Kettles that are used once and recycled are double steam cleaned to make them safer.

Steam cleaning of lids

Before use, kettles and lids are sterilized by steam cleaning at 85°C.

Production line cleaning

At least six times a day. The production line is stopped and carefully cleaned.

sterilizing lamp

UV sterilization lights are installed throughout the plant. This reduces the number of bacteria that fall out.

Implementation of 3S5T

In order to maintain a hygienic environment, we implement the 3Ss (sorting, setting in order, and cleaning), and the 5Ts (fixed route, fixed position, fixed display, fixed quantity, and fixed color) on a daily basis.

Inspection and acceptance of raw materials

Records the surface temperature of food ingredients, expiration date and quantity, date of processing, and response to abnormal conditions.

Oginoya Co.

With 138 years of tradition,

Keeping Food Safe

In our 138-year history, we at 荻野屋 Corporation have focused on creating and improving the sanitary environment in all food-related processes. The traditions and experiences handed down from the time of our founding are our most important assets, and the hygiene management know-how we have developed through these efforts continues to be of value even today.

From the past to the present, we have established our own strict hygiene standards and worked to create a sanitary environment. In particular, during the reign of Mineji Takamizawa, the fourth generation of 荻野屋 employees, we thoroughly implemented the ideas that form the basis of 荻野屋's current sanitary environment, which has become the foundation of 荻野屋's current quality control. We have worked for many years to create a hygienic environment in all of 荻野屋's locations, including factories, kitchens, and stores, based on the idea that a hygienic environment is the foundation of customer hospitality.

As a result, we have received numerous awards from the Minister of Health and Welfare and other food sanitation associations, and have been recognized by government agencies for our achievements in food sanitation. This is the result of our continuous efforts over the past 138 years to earn the trust of our customers, which we value the most. In 2010, we acquired voluntary food hygiene management certification in accordance with HACCP, and we are working more actively to build a food hygiene environment. We are uncompromising in our efforts to build a hygienic environment and regularly check the quality and sanitary conditions of our products in our daily operations to ensure that they are always in tip-top condition.

Always wash hands before gloves and wear gloves with clean hands.

apply an adhesive roller

Take dust and hair around the face and upper body

- When food ingredients are changed (when handling heated or unheated foods)

- When serving ingredients change

- When touching non-food items

- When damaged

- When used for different purposes

Received the Minister of Health and Welfare Award for its leading hygiene management standards in Japan.

In addition, we received the Chairman's Award as an excellent food hygiene facility from the Japan Food Association.

OGINOYA's commitment to "safety and security" proved to be at a level that is representative of Japan.

Then again in 2009, the central kitchen received the Minister of Health, Labor and Welfare Award.

| Received the Minister of Health and Welfare Award | |

| 1994 Suwa branch | Received the Nagano Governor's Award for Excellent Sanitation Facility |

| 1999 Suwa Manufacturing Plant | Received the Minister of Health, Labor and Welfare Award |

| 2009 Yokokawa manufacturing plant | Received the Minister of Health, Labor and Welfare Award |

| 2010 Yokokawa Manufacturing Plant | Gunma Prefecture Food Voluntary Hygiene Control Certification acquired. |

| 2010 Suwa Manufacturing Plant | Received the Minister of Health, Labor and Welfare Award |

| 2014 Nagano Branch | Certified as a 5-star restaurant for food safety and security by the Japan Food Sanitation Association |

| 2018 Suwa Branch | Nagano Food Sanitation Association Suwa Branch certified as a 5-star restaurant for food safety and security |

Indicators and Criteria for Evaluation

The central kitchen received Gunma Prefecture Voluntary Food Sanitation Management Certification in 2010.

The central kitchen received Gunma Prefecture Voluntary Food Sanitation Management Certification in 2010.

We hereby announce our most important control items and food safety policy, and we will continue to be proactive in our hygiene management.

- We check the expiration dates of the ingredients used.

- The container is disinfected before use.

- Heating temperatures are measured and recorded for each product.

- We produce Touge no kamameshi in a clean kitchen.

- We will ensure compliance (legal observance).

- We produce products that our customers can enjoy with confidence.

- Clenliness is the basis of our work.

荻野屋 complies with HACCP standards and works closely with traders and all relevant stakeholders to ensure sanitation throughout the supply chain. Below is a description of our specific efforts throughout the supply chain process.

HACCP-based purchasing standards: We purchase food ingredients based on HACCP-based quality and sanitation standards shared with our suppliers.

Supplier HACCP implementation status checks: Regularly check that suppliers are following HACCP guidelines and provide feedback.

Identify critical control points: identify steps or processes to prevent, eliminate, or reduce hazards to acceptable levels.

Audit of the sanitary condition of transport vehicles: In collaboration with our suppliers, we regularly audit the sanitary condition of our transport vehicles and make necessary improvements.

Product freshness and quality control: Temperature and humidity during product storage and display are strictly controlled in accordance with HACCP standards.

荻野屋 has established a consistent hygiene management system compliant with HACCP standards through the above efforts. We are also working closely with stakeholders to ensure food safety and quality.

- Records surface temperature of food ingredients, expiration date, quantity, processing date, and response to abnormal conditions

- first in, first out

- Transfer from outer bag to clean container

- Cleaning and disinfection of utensils used for preparation (disinfection: immersion in 240 ppm sodium hypochlorite solution)

- Attach the date of preprocessing

- Wash and disinfect containers and utensils each time they are used (disinfection: soaking in 240 ppm sodium hypochlorite solution)

- Records of taste, odor, color, turbidity, and response to abnormalities of water used

- Measure and record center temperature during heating (basic: center temperature 95°C or higher; quail eggs: 85°C or higher; apricots: 75°C for 1 minute or higher)

- When a vacuum cooler is used after heating, the surface temperature after cooling is measured and recorded.

- Records rice cooking time, number of kettles, presence of foreign matter, and center temperature

- Taste check conducted

- Before and after work begins Disinfect workbench and conveyor tops (wipe with a cloth soaked in 240 ppm sodium hypochlorite solution)

- Wear disposable gloves (check for holes or tears, replace when moving to another job or when torn)

- Record the time from boiling up to the start of serving, collect food samples, store frozen (14 days), and record in the food inspection record book.

- Record the start and end time of serving, the name of the person in charge of serving, and the presence or absence of foreign objects (and the response when found).

- Disinfected hand rags and table cloths are placed on serving tables and conveyors Hand washing and changing of disinfected cloths every 30 minutes

- After using gloves, remove them away from food and utensils and dispose of them in a dedicated trash bin.

- Product storage room temperature: 25°C or less

- Adjustment printout checks, shipping records, and delivery departure times are recorded.

- Records temperature of delivery vehicles, cleaning and disinfection, and response to abnormalities

荻野屋 Corporation.

Facility Cleaning and Maintenance Initiatives

We, 荻野屋 Inc,

We recognize that the condition of our facilities directly affects the quality of our products, and we make every effort to preserve them.

荻野屋 has developed a management system that integrates sanitation and equipment maintenance. These are embodied through employee daily codes of conduct, processes, and checklists that are shared with the entire team. With our 138 years of experience, we have earned the trust of our customers by continuing to uphold food safety and quality. We will continue to maintain this stance and always deliver products of the highest quality.

And 荻野屋 is taking the following specific steps to create a sanitary environment.

Through our efforts, 荻野屋 Inc. is at the forefront of protecting product safety and quality. Proper management of our facilities is the foundation for providing reliable products to our customers.

A hygiene management department is also set up at each drive-in. Safety and security" are also provided at the point of sale.

In addition, the 1st and 15th of each month are designated as "Cleanliness Days. Twice a month, we contribute to the community by thoroughly cleaning the store and also by cleaning the area around the drive-in.

The high quality food and boxed lunches that 荻野屋 has been providing for many years are supported by our strict adherence to sanitation.

As part of our internal auditing system for sanitation, people from specialized departments regularly inspect the sanitary environment in accordance with our established in-house sanitation standards under the advice of an external organization. In addition to regular inspections by our hygiene advisors, we also receive regular inspections and evaluations of the sanitary environment from external specialized agencies such as JR East and public health centers.

荻野屋 believes that maintaining an inspection and audit system from an outside agency has the following significance

We are confident that our 138 years of history and experience will continue to empower us to deliver the best products, safety and reliability to our customers.